THERMAL ENERGY AUDIT IN PUNE,MAHARASHTRA

These Thermal energy audit aim towards determining efficiencies of generation, distribution & utilization of thermal energies. These are based on Efficient Studies that will be conducted for Boilers, Furnaces, Thermo packs, Ovens and Hot Air and Generators.

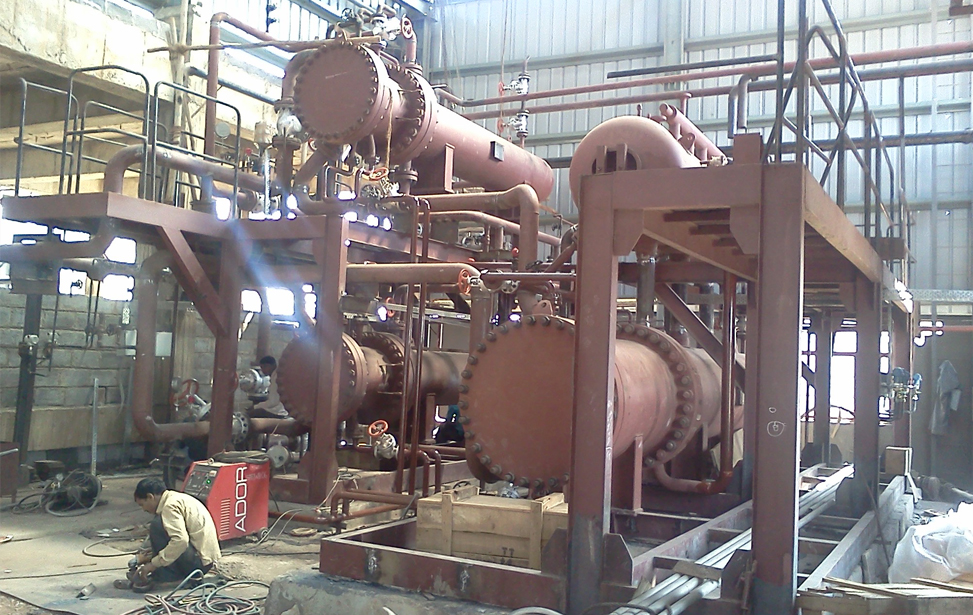

Studies are undertaken to determine efficiencies of generation, distribution & Utilization of thermal energies. Boiler efficiency tests are carried out to determine steam generation to fuel ratio. Condensates coming from coil, jackets, evaporators are collected to arrive at norms for each operation. Exhausts of furnaces, boilers are quantified by analyzing them with our set of equipments. Fixed heating load, start up load & insulation losses are determines. Based on the above results thermal energy balance is struck for reference period of one year.

Based on the energy losses identified in the thermal energy balance, energy conservation measures are presented with techno economic analysis. The energy saving areas normally identified are:Improvement in steam / power generation efficiency, house keeping measures, waste heat recovery, optimal choice of fuel, process optimization etc. Time bound implementation programs are drawn with company manager. We have carried out eighty such audits, mainly in process industries in India. We have achieved savings ranging from 4 to 30 % in the thermal energy expenses of our clients.

Main steps of the Encon's audit procedure

Data acquisition and visualization of the status quo

Energy demand reduction through process optimization

Heat recovery through an intelligent combination of heat exchangers, estimated through the pinch analysis

Integration of renewable energy sources and high technology equipment, such as solar heating and cooling.

Thermal Audit for

Heat pump technologies

CHP systems

Boilers and burners

Cooling and air condition

Heating and cooling supply to buildings

Furnaces

All Thermal Equipments