Noise is one of the major forms of pollution. Results of noise pollution are very dangerous and hence we need to have control on noise level.

In order to meet environmental standards noise reduction requirements continue to increase. Noise limits for the avoidance of hearing damage should be less than 85 dB of continuous source and less than 110 dB of intermittent source.

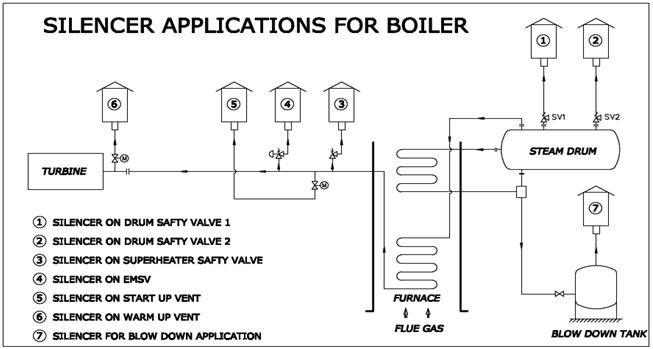

Steam / Air is vented from boiler / Equipments, either from exhaust valves, vent valves, safety valve or from start up/ warm up vent valves. Very high level of sound (approx 160 dB to 175 dB) is generated when steam / air is vented from elevated pressure to atmospheric pressure. It is harmful to plant people and is also audible over large distance, hence equally harmful to society around. Our product silencer is specially designed to reduce this sound level to around 85 to 110 dB that is to safety zone.

Our design of silencer is completely customized suitable for customers’ requirements and site conditions. For Silencer design we follow guidelines as per OSHA, basic principle of acoustic & mechanical design is as per ASME sec VIII div.I.

Applications

We design and manufacture silencers for

Superheated steam

Saturated steam

Start up and warm up vents

Blow down applications

For any other Steam / Air / Nitrogen vents

Range – Our design of silencer is completely customized as per our customers’ requirements. We have wide range of silencers from 0.5TPH to 100TPH steam / air flow and for pressure 1kg/cm²(g) to 150kg/cm²(g). Generally we recommend to erect silencer vertically but for space constraints we can provide horizontal as well as inclined designs too.

Required Design Input Parameters

Following input parameters are required to design silencer –

Steam flow rate in kg/hr

Steam inlet temperature to silencer (⁰C)

Steam inlet pressure to silencer (kg/cm²)

Inlet pipe size

Elevation level of silencer from ground