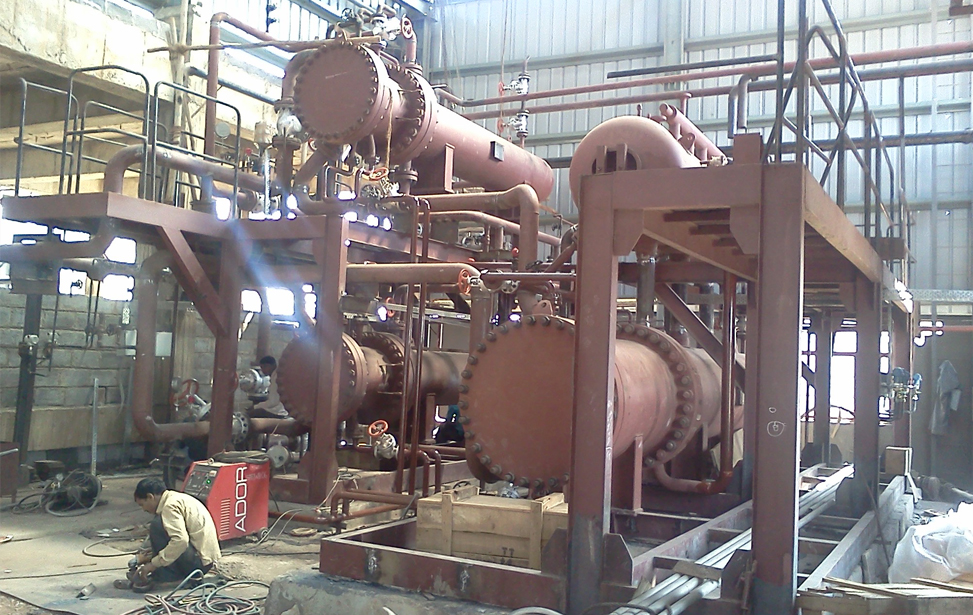

HEAT TRANSFER EQUIPMENTS Manufacturers in Pune,Maharashtra

Process equipment and streams will need to be heated or cooled. One way to reduce consumption of utilities is to exchange heat between these streams. Heat exchangers are widely seen across various types of industry, mainly for heating and cooling large processes. Depending on the process, the type and size of heat exchanger can be tailored depending on certain factors. These factors include the types of fluid that will engage in heat transfer, the phase, densities, temperatures, pressures, and various other thermodynamic properties of the fluids. Heat exchangers can save companies a lot of money by reusing the energy or heat in a waste stream and using it to heat or cool a different stream in the process that is vital. There are many industries that utilize heat exchangers, including the following:

- Waste Heat Management

- Oil, Gas, and Petroleum Processing

- Chemical Processing

- Cryogenic Air Separation

- Power Generation

- Refrigeration

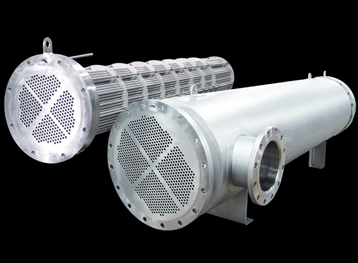

We have designed customized Heat Transfer Equipments like Transient Heaters, Shell and Tube Heat Exchangers, Condensers, HP and LP Heaters, Air/Gas Pre Heaters etc.

DEHUMIDIFIER

Name itself indicates that this equipment is for de-humidification i.e. de-moisturising. Moist air or inret gases are dehumidified or dried in this equipment. Costruction is of finned tube type and hence the equipment has become very compact. Eqipment is designed in detachable modules and any nodule can be removed for inspection or maintenance without disturbing other modules.

Chilled water (2 to 4 deg. celsius) flows inside tubes and air or gas which need to dehumidified flows over finned tubes. Removed moisture collects in bottom sump and removed from common bottom drain. At air or gas exit mist eleminator or sometimes demister pads are provided to further improve the quality of dryness of the air or gas.

Make an enquiry