ENCON ENERGY AND AIR SOLUTIONS PUNE,MAHARASHTRA is a consultancy and Project Company for all kind of Thermal Engineering Projects (Specifically in Waste Heat Recovery solutions), Thermal Engineering, Flow and Noise Control. We undertakes "Design Consultancy" as well as "Turnkey projects". We have proven Thermal designs as well as Mechanical designs which are in working at various industries.

Mr. Shrikant Pawar, Director Technical is associated with heat transfer field from last two decade and have a versatile experience specially in the field of Waste Heat Recovery (WHR), Thermal Projects, Mini Steam & Hot Air / Gas Generators, Drying equipments (Tray, Rotary and Vacuum Dryers), Air Dryers, Noise control equipments (Mufflers and Silencers), Flow Switches, Level Controllers, Flow Meters Food Preservation systems.

Under Engineering Services we do Air and Thermal Audits, Furnace performance testing, Indoor / Outdoor Air quality testing, Flue Gas Analysis and Sound Level Testing. We Undertakes Furnace efficiency improvement program and Conducts Thermal Audits. We also organize “Industrial Training Programs” on Energy Conservation and Performance Calculations for various thermal equipments.

Our Focus

Our Focus is Thermal and Energy Conservation needs. Our motive is "Waste Heat Recovery" and "to design and supply heat transfer equipments for right specifications, to appropriate cost with innovative technology for customer delight". Our prime goal is to recover all kind of waste Energy and to reuse it again for some useful work.

Design Capabilities

Dryers

Dryers on fluidized bed principle for coke, iron ore, sand, slag, tea leafs etc.

Competency in

Combustion calculations, heat transfer (sizing) calculations, hydraulic calculations, control philosophy ,mechanical CODE calculations, piping design & stress analysis, vibration analysis, refractory & ceramic engineering etc.

Refrigeration Systems

Knowledge of VCR and VAR systems. Specific knowledge of air dryers (refrigerated as well as descicant dryers), Air piping design, Clean rooms, Environmenntal chambers etc. We also deal in auto drain valves and compressed air after and precoolers.

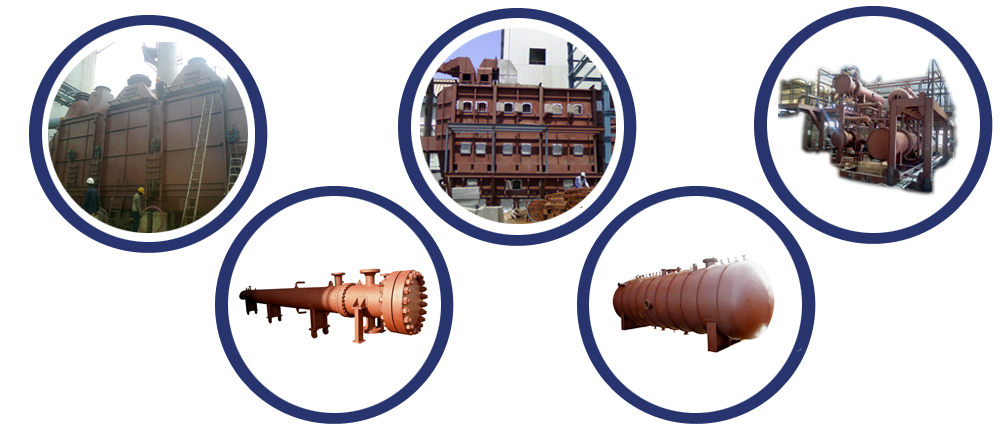

Heat Recovery Systems

Process Integrated - Systems handled in Metallurgical industry, Chemical industry, Petroleum refineries, Petro-chemical industry, Fertilizer industry, incinerators etc. Knowledge of upstream and downstream processes linked with the Process Integrated Boilers. WHRS on waste flue gases of DG sets, Gas turbines, Incinerators, Furnaces etc

Power Plants & Cycle design

medium scale (0.5 to 15MW). Thermal-hydraulic balance sheet preparation. Sizing of steam circuit, cooling water circuit,DM water circuit, Fuel and ash circuit, specifications of Boilers, turbines, regeneration system, pollution control equipment’s etc.

Regeneration systems

like- LP heaters, HP heaters, Deareators, Condensers etc. Designed various equipment’s like economizers, air pre-heaters, capacity Enhancement of working boilers, changing of combustion systems etc. Refractory engineering for cement plant equipment’s, furnaces and heaters. Technical feasibility reports made on Solar Energy based Power plant.

Knowledge of

IBR, ASME SEC I, BS 1113, BS 2750, TRD for Boiler design. TEMA for Heat Exchanger design

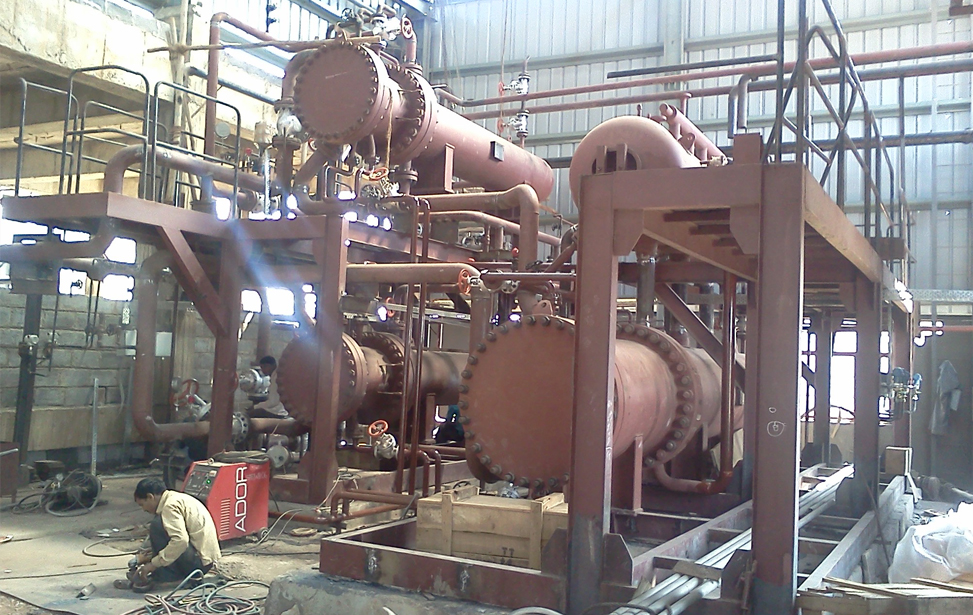

Manufacturing Capabilities

In association with channel partners we undertake manufacturing of WHR, Thermal and Fabrication Projects. We have well equipped manufacturing shop located at Bhosari Industrial Estate (M.I.D.C. Bhosari) in Pune District. Being located in M.I.D.C. all requiried facilities like Laser cutting, Machining, Thock sheet bending. Dished End forming, Pipe and Tube bending etc. is available within an area of 1.5 Sq. Km. In our fabrication shop we have facility of TIG welding, MIG welding, Machining, Grinding, NDT testings like DP test, Pneumatic testing, Hudro tesing are available. We can arrange Rediagraphi testing in house by hiring trained and authorised agency. Almost three NABL approved labs are present withine 2 Km span. We have our own lifting facilities up to 5 Ton and can hire up 100 Ton lifting capacity easily at any time. At present we have 10000 sq. ft. well equiped shop floorfor all kind of heavy engineering jobs.

Mission of Company

Design, Manufacture and supply of heat transfer equipments for right specification, to appropriate cost with innovative technology for customers delight.