Economizers

Economizers are the last stage of the feed water system. They are designed to extract heat value from exhaust gases to heat the steam still further and improve the efficiency of the boiler. They are simple finned tube heat exchangers. Not all boilers have economizers. Usually they are found only on water tube boilers using fossil fuel as an energy conservation measure.

A feed water economizer reduces steam boiler fuel requirements by transferring heat from the flue gas to incoming feed water. By recovering waste heat, an economizer can often reduce fuel requirements by 5 per cent to 10 per cent and pay for itself in less than two years.

A feed water economizer is appropriate when insufficient heat transfer surface exists within the boiler to remove combustion heat. Boilers that exceed 100 boiler hp, operating at pressures exceeding 75 psig or above, and those that are significantly loaded all year long are excellent candidates for economizer retrofit

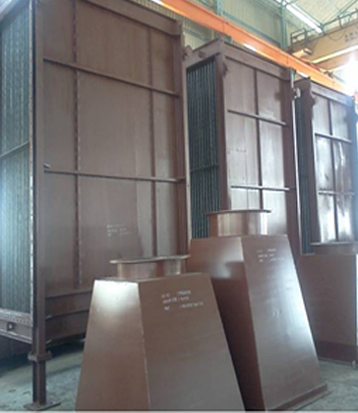

AIR PREHEATER

An air preheater (APH) is a general term to describe any device designed to heat air before another process (for example, combustion in a boiler) with the primary objective of increasing the thermal efficiency of the process. They may be used alone or to replace a recuperative heat system or to replace a steam coil.

The purpose of the air preheater is to recover the heat from the boiler flue gas which increases the thermal efficiency of the boiler by reducing the useful heat lost in the flue gas. As a consequence, the flue gases are also conveyed to the flue gas stack (or chimney) at a lower temperature, allowing simplified design of the conveyance system and the flue gas stack. It also allows control over the temperature of gases leaving the stack.

Dosing System

Our LP and HP chemical dosing system is an exclusive device, which is used in petrochemical, power, fertilizer and other processing industries. The apparatus applied for dosing consists of a preparatory vessel, agitator, metering pumps, interconnecting piping, all mounted on a common skid. In this system the feed water is used with chemical so that there is no scaling inside the boiler. The HP chemical dosing system is used in boiler house, effluent treatment plants, and water treatment plants or in a process where controlled volume feeding of liquid is required.

Deaerator

Pressure of oxygen in feed water is always harmful to boilers it corrodes metal parts.Deaerators are used to remove free Oxygen from boiler feed water performance of Deaerator is depend upon effective method of activity maximum water and steam surface contact with higher time of contact.

Our design achieves these requirements very efficiently by planned spray pattern, highly effective scrubbing by multiple tray arrangement and mixing incoming steam with water. We can residual O2 level below 0.007 PPM after deaeration which satisfies requirement of modern high boilers.

Steam Vent Silencer

We follow international standards of quality to manufacture a precision engineered range of industrial silencers for safety valve, start up vent, super heater, throttling valve etc. These are uniquely designed and developed as per the specifications & requirements as laid down by the clients. These industrial silencers are offered at industry leading prices and are reckoned for superior quality features such as durability, corrosion resistance, high tensile strength and many others.

Application:=These industrial silencers are known to effectively control and vent noise caused by safety valve, throttling valve/control and valve. This also wide usage for air, steam and other process gases at varied pressure and temperature condition.

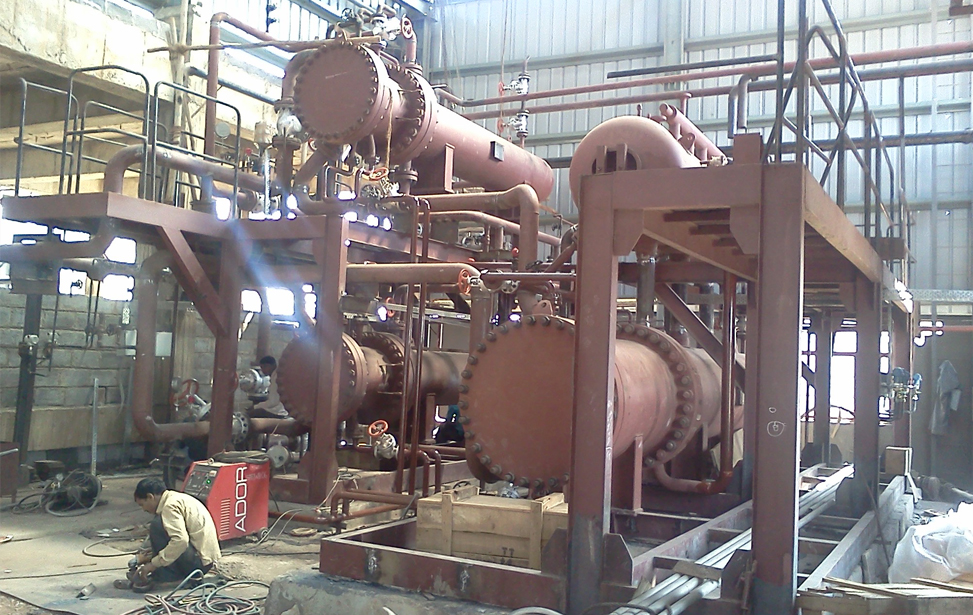

HP and LP Feed Water Heaters

It is the most common type of heat exchanger in oil refineries and other large chemical processes, and is suited for higher-pressure applications. As its name implies, this type of heat exchanger consists of a shell (a large pressure vessel) with a bundle of tubes inside it. One fluid runs through the tubes, and another fluid flows over the tubes (through the shell) to transfer heat between the two fluids. The set of tubes is called a tube bundle, and may be composed of several types of tubes: plain, longitudinally finned, etc

Steam Accumulators

The purpose of a steam accumulator is to release steam when the demand is greater than the boiler’s ability to supply at that time, and to accept steam when demand is low. Steam accumulators are sometimes thought of as relics of the ‘steam age’ with little application in modern industry. It is a type of energy storage device. It can be used to smooth out peaks and troughs in demand for steam.

Make an enquiry